| What

is TrueMill?

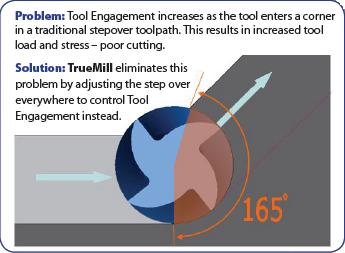

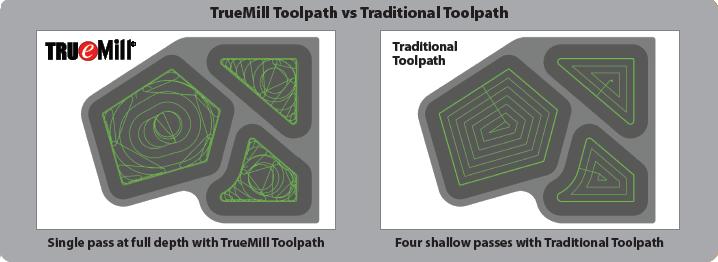

TrueMill is

a patented toolpath that controls

the tool’s engagement with the

material to deliver faster

and

deeper cutting

than any other 2 & 3 axis

roughing toolpath - in all materials.

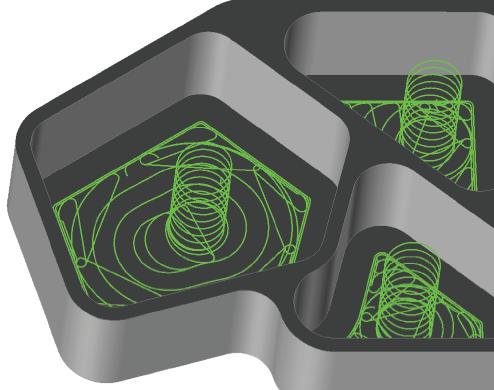

TrueMill

Benefits:

Greater

Depth of Cuts

Higher

Feed Rates

Higher

Material

Removal Rates

Reduced

Cycle Times

Increased

Tool Life

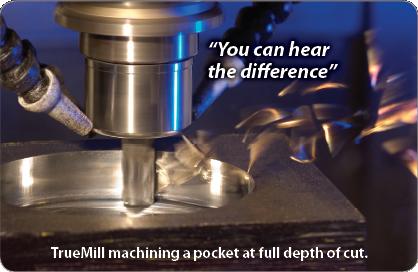

See the

difference in TrueMill chips!

|

Truly

Amazing!

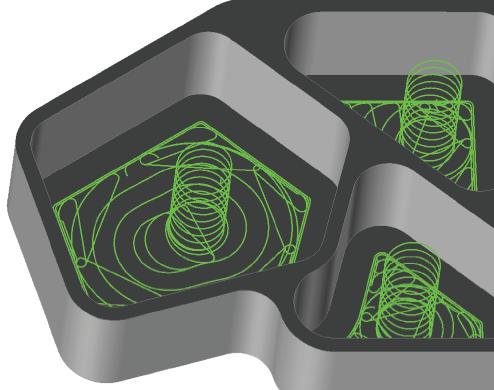

TrueMill

toolpaths as machined on a Haas VF3 CNC Machine |

| Material |

Aluminum 6061 |

Titanium 6AL4V |

Steel – ToolOx (45 Rc) |

| Endmill |

.500” Dia. |

.500” Dia. |

.500” Dia. |

| Depth |

1.000” |

1.000” |

1.000” |

| Speed |

8911 rpm |

3438 rpm |

10000 rpm |

| Feed |

300 ipm |

115 ipm |

180 ipm |

| Max SO* |

.250” |

.035” |

.058” |

| Peak MRR** |

75.00 in3 |

4.03 in3 |

10.53 in3 |

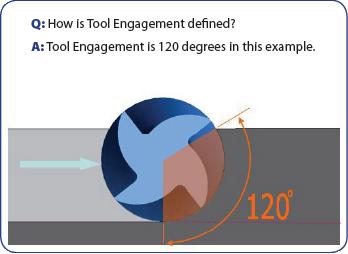

| TEA*** |

90.0º |

30.7º |

40.0º |

* Maximum equivalent

(true) step over

** Peak Material Removal Rate

*** Tool Engagement Angle |

|

|

|